Our Export Process

Our Business

While approaching international market we are sought to keep our clients interest our priority, keeping up the technologies and methods and the quality of tobacco leaves. We also let our clients rely on trusted FDA approved laboratories. Our labor-intensive methods help up with quality control all over the levels.

Curing Techniques

The harvested tobacco undergoes curing to develop its specific characteristics, such as color, texture, aroma, and flavor. Curing also removes moisture from the leaf. We practice two major curing techniques based on the type of tobacco:

Air cured Tobacco

In well-ventilated barns without any heating source, leaves are hung to dry. This air curing method is used for producing cigars and burley tobacco.

Sun cured Tobacco

Uncovered tobacco is naturally sun-dried. This method is used for sun-cured oriental and burley tobacco types.

Grading

Cured leaves are manually sorted into uniform lots based on the plants’ stalk positions, quality, and color or according to the use and type of tobacco end consumption. Central Tobacco Research Institute (CTRI) grade standards, ensuring consistent quality over time. Refer to Tobacco Type to check different uses and varieties.

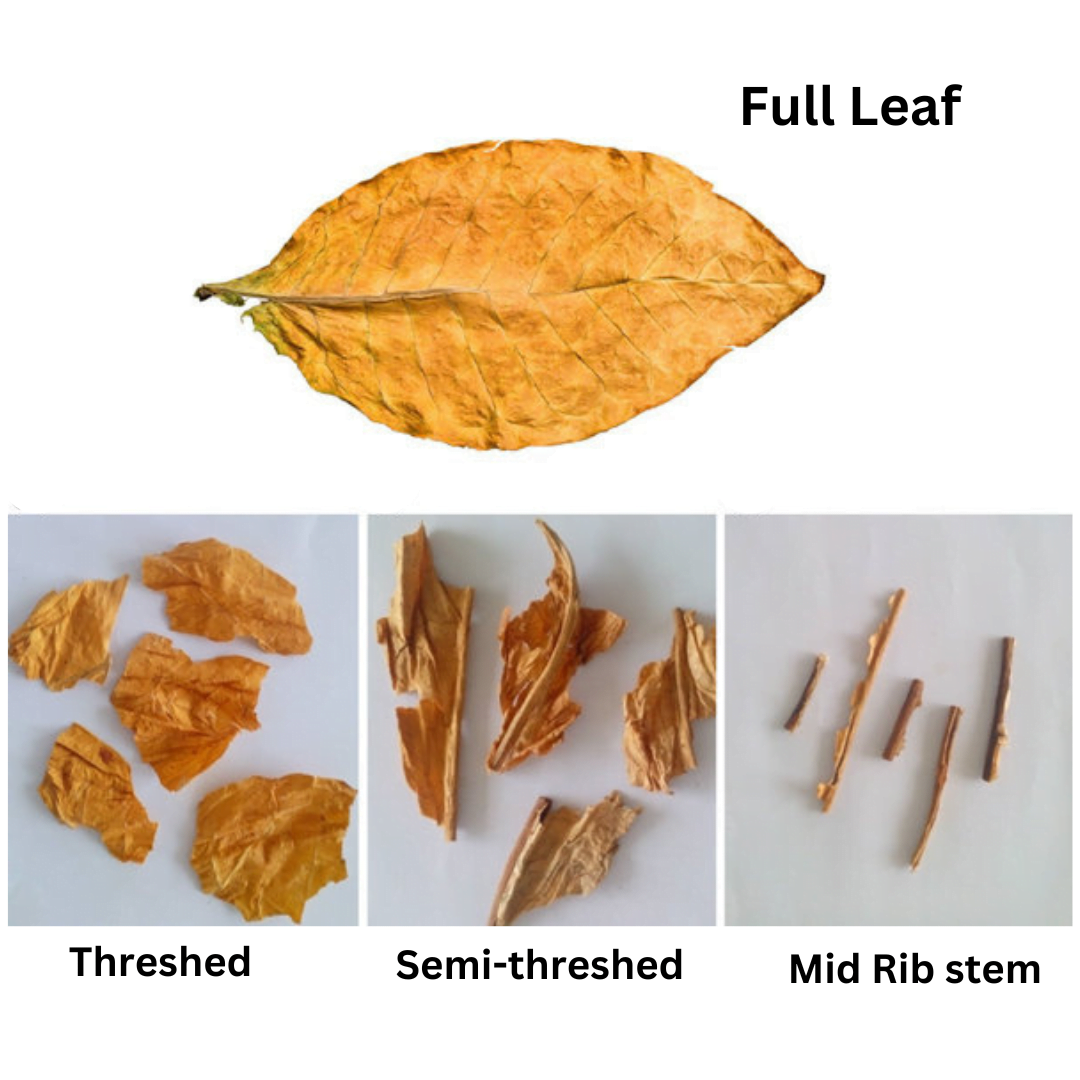

Threshing

The lamina is separated from the stem and re-dried to maintain consistent and homogeneous moisture levels throughout the batch. This labor-intensive process ensures quality control. Most graded tobacco is threshed, while some is hand-stripped for specific applications. Re-drying and conditioning ensure the ideal safe storage moisture content, even if the order requirement is restricted to the following:

Packing

Threshed lamina (RTL) is typically packed in gunny bags, bale board packs and CFB cartons, with net weights ranging from 30 to 200 kg. The packaging is then delivered to the client’s warehouse or plant.